Every business wants to make sure that their equipment and machinery is working as well as possible. Any problems need to be identified as soon as possible, which requires that the performance of this machinery is tracked at all times.

The job of tracking the performance is the job of a computerised maintenance management system.

When you want to improve the efficiency of your equipment and employees, you need to understand the root causes behind why inefficiency occurs and how things can be improved upon.

The job of highlighting inefficiency and working out ways to improve the situation is the job of an overall equipment effectiveness systems.

How Does The CMMS Software Work?

The CMMS software allows maintenance teams to track the performance of equipment and machines. The data is provided in real-time so that problems can be identified as soon as they occur. Maintenance staff can respond quickly to the problem, which will save the business both time and money. Problems could remain undetected for a long period of time if your company has not invested in some high-quality CMMS software. Visit www.idhammarsystems.com for quality CMMS software.

The layout of the CMMS software is extremely simple so that all the relevant data is easy to understand. When people use complicated maintenance systems with poor layouts, they might not be able to pick out the relevant data.

The CMMS system manages the operating and inventory costs of the business equipment, so you will be able to see exactly how much money is being spent on running and repairing of the machinery. This data can be factored into your monthly expenditure reports.

The CMMS system will reduce machine downtime because the maintenance team will be able to see problems occurring in real time. If the system is not in place, the problem could go undetected for a while.

How Does The OEE System Work?

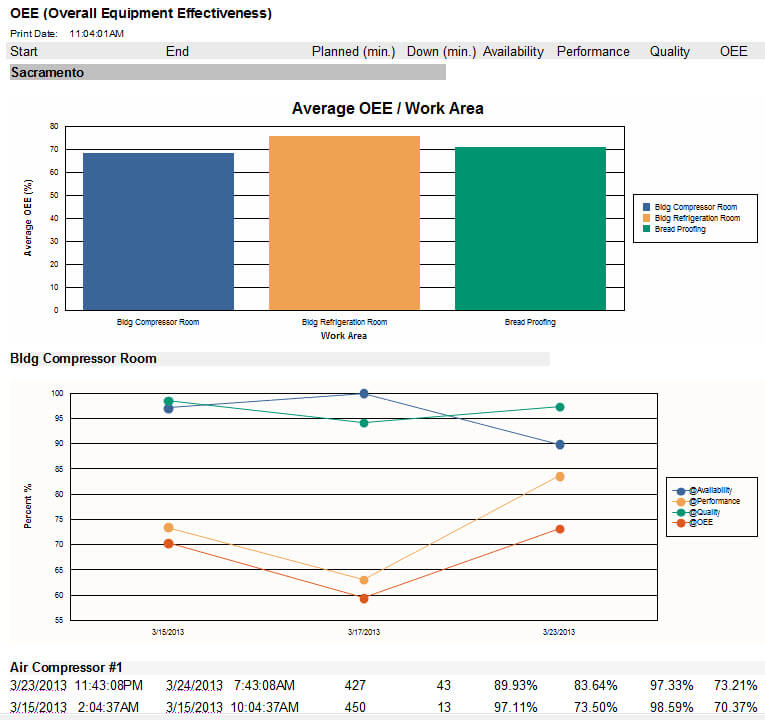

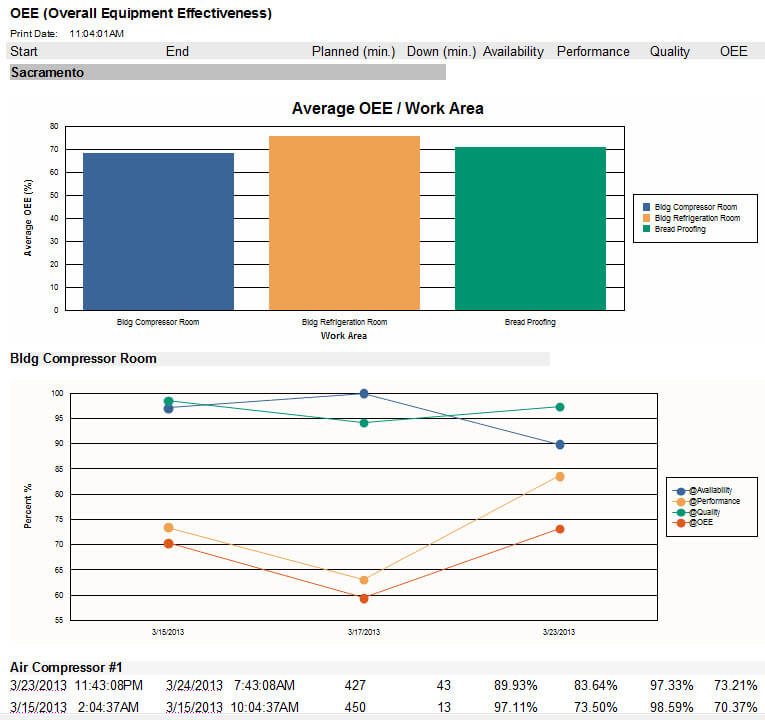

The OEE system is designed to identify problems with efficiency and to suggest solutions on how the efficiency of machines and equipment can be improved. This builds on the job of the CMMS software, which is tracking the performance in real time.

The OEE system is laid out in an easy-to-understand fashion so that the efficiency data can be clearly understood and acted upon.

This system helps you to identify why inefficiency is occurring. This is done through the Root Cause Analysis Tool. You might not have time to work out why equipment is inefficient when you are dealing with other aspects of your business. The OEE system does that job for you and takes a lot of pressure off your shoulders.

In order to make your business run as smoothly as possible, it is a good idea to invest in both a computerised maintenance management system and an overall equipment effectiveness system. Research several different providers and study their products carefully. Then you will be able to make an informed decision on which products to buy.