A ball mill is a grinding machine popular for grinding and mixing material together into powder form. The size of metal is reduced by balls falling over the surface of metal. The machine is popular for mixing paints, grinding flour for baking and other materials. It consists of rotating cylinders that further contains balls responsible for grinding. Ball mills manufacturers in India are using mainly three types of ball machines – horizontal, vertical, and industrial. Let us have a close look at each type one by one –

Horizontal Ball Mills

Horizontal ball mills is most favorite type of ball Mills manufacturers in India. Basic design is same for all types but detailed specifications may vary accordingly. The horizontal ball mill has a drum inside where material is loaded for further processing. This drum is usually detachable and larger in size. Balls are also fixed inside and they are controlled through special screen. Once the material is loaded inside the drum, the door should be closed properly for accurate processing. Make sure drum is reinstalled horizontally and door is closed properly. Few machines have timers and other have visible windows where processed material can be observed closely.

Vertical Ball Mills

Vertical Ball mills are especially intended for laboratory or shop use. These are small in size like a blender useful for mini tasks only. They can be easily fit into workshops or laboratories and small enough to process desktop apps only. In other words, vertical ball mills cannot be installed for commercial or industrial use. They are also popular as planetary ball mills in market. Unlike horizontal ball mills, drum inside vertical machine is not detachable. Just add the material from top and close the cap like a kitchen blender. Vertical ball mills are usually available with variety of ball sizes for more efficient and quick processing.

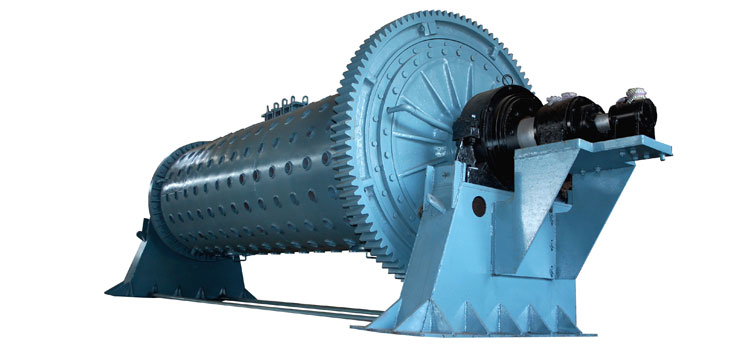

Industrial Ball Mills

As the name suggest, industrial ball mills are especially intended for industrial use and much larger as compared to vertical and horizontal ball mills. Their size may vary from refrigerator to a bus. Industrial ball mills are always horizontal. The larger unit has multiple chambers that force material to move continuously inside drum. The multiple chambers are separated through screen between them. Each chamber has balls smaller in size. Screen controls the different chambers together so that balls should not be mixed inside chambers. Material is forced from one chamber to other automatically for fine grinding.