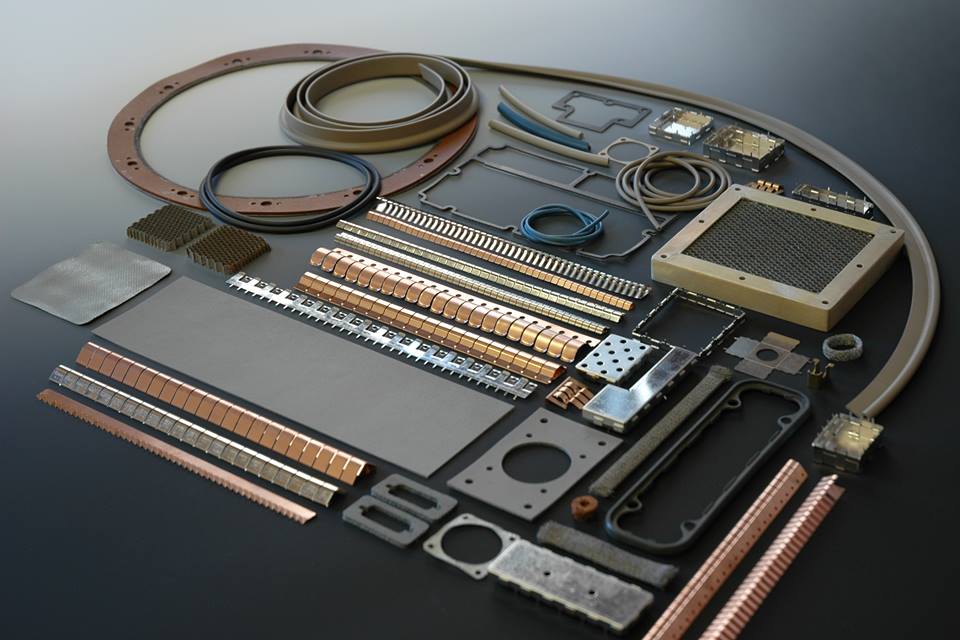

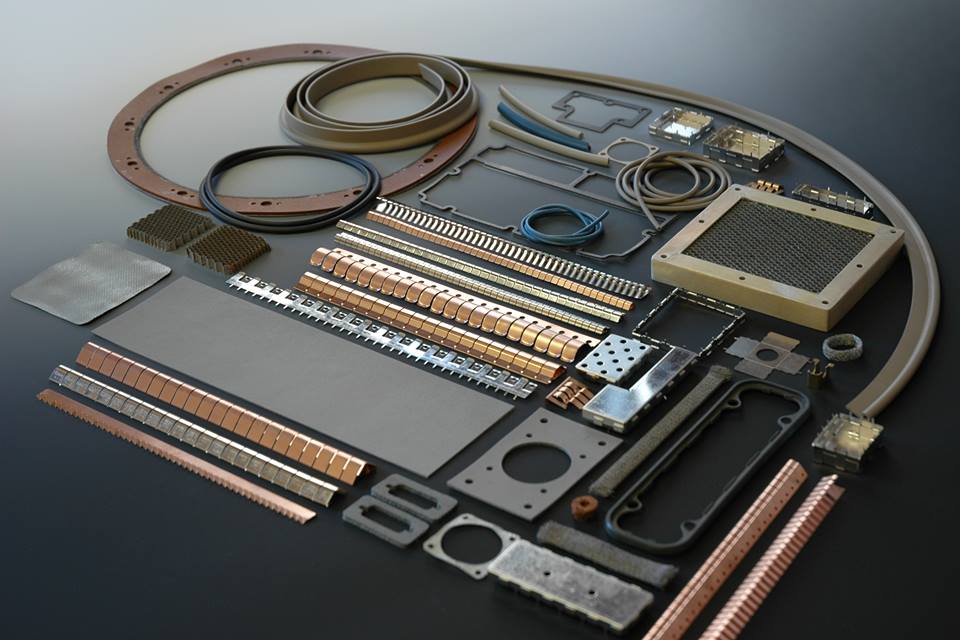

Conductive Elastomers are one of the leading magnetic shielding materials. One can define it as fully cured silicones or fluoro-silicones that are loaded with different types highly conductive metal particles. These particles offer superior Electro Magnetic Interference (EMI) shielding performance. These metal particles also provide outstanding environmental sealing for water and dust. The different conductive fillers are designed as such to ensure galvanic compatibility along with providing resistance to low contact between surfaces. The elastomers are easily mouldable, hardwearing and durable. They are also extremely efficient in conducting electrical current and in shielding units from radio frequencies, and environmental and electromagnetic interferences.

What Makes Conductive Elastomers the Right EMI Shielding Solution?

The four reasons that often make conductive elastomers the right choice as EMI shielding solutions are:

- Easy availability

- Flexibility of designing

- Proven performance

- Cost effectiveness

Properties of Conductive Elastomers

Conductive elastomers are synthetic silicone rubbers that have utilitarian physical and chemical properties over an extensive range of temperatures. Mainly comprising silicone, conductive elastomers provide resistance against UV light, oxidation, moisture, weathering, and a number of chemicals. These elastomers are permeable and flexible as well, along with being non-irritating to the human skin.

What Makes Conductive Elastomers CONDUCTIVE?

As mentioned earlier, conductive elastomers are primarily made of silicone. But silicone is not electrically conductive in nature. In fact, silicone can act as a good electrical insulator and often finds an application with high voltage equipment. Then how do conductive elastomers conduct electricity? It is the metal particles added with silicone while making these elastomers that make them electrically conductive. Hence, they provide excellent resistance to electromagnetic interferences.

Tear Resistance and Tensile Strength of Conductive Elastomers

Tensile strength and tear resistance are inter-related concepts. When you cut a small part of a particle-filled conductive elastomers into a thin cross section, lack of enough tensile strength may cause tearing. Such tears can lead to loss of conductive seal and let RF waves to enter. This is the reason why experts recommend reinforcing an inner layer of conductive mesh or fabric with EMI shielding conductive elastomers.

Material Hardness of Conductive Elastomers

EMI shielding conductive elastomers that are made of tough material may not be able to resist water, chemicals, and contaminants, or support compression. So, designers suggest using EMI shielding silicones that are filled with nickel coated graphite or silver plated aluminium. Such shielding elastomers are ultra soft, in fact softer than any other material used for EMI shielding. This in turn also satisfies the preference for higher tensile strength and tear resistance.

Cost Effectiveness and Material Performance of Conductive Elastomers

While analyzing the right kind of EMI shielding elastomers, apart from the material properties, you must consider the product’s cost effectiveness. Though conductive silicones filled with silver-coated aluminium particles offer brilliant shielding effectiveness, silver is extremely volatile in the market of precious metals. The cost effectiveness of conductive silicone elastomers is inversely proportionate to the price of silver, so if the price of silver rises in the market, manufacturers may suffer huge cost overruns, which will automatically increase the price of silver-induced conductive silicones. Under such circumstances, EMI shielding conductive elastomers filled with nickel-coated graphite presents itself as a good alternative. But don’t keep a doubt about the performance of nickel-graphite shielding elastomers, as these are as good and effective as the silver-coated counterparts.

If you are looking for magnetic shielding materials, get in touch with a solutions provider that offers a wide range of cost-effective options. Find out if their products has an impressive list of application in manufacturing enclosure shielding products like sheets, extrusions, diecasts, O-rings, waveguides, and form-in-place.