A chain hoist is commonly used to lift heavy loads through a pulley or drum that optimizes the moving direction and multiplies force to make pulling quite easier. Chain hoists come in bevy of configurations to handle different weights. Lever hoists and manual chain hoists are two major hoist categories that are extensively used in distinct industrial applications.

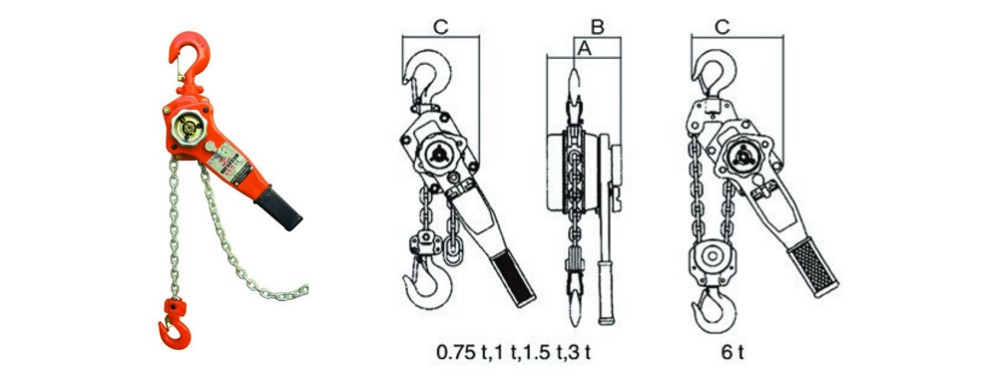

Lever hoists, a reliable lifting equipment, deliver versatile lifting capacity that is unmatchable with the results delivered by jib cranes or hydraulic jacks. Being flexible in mobility, lever hoists are also a cost-effective solution in demanding work environment. A lever hoist requires low pulling force for effortless lifting operation.

Lever hoists are generally designed for free wheel to allow swift movement of the unloaded lifting chain. They manage 360 degree rotation of both the lever and the top swivel hook which is necessary for easy rigging practices. Some lever hoist versions come packed with an optional carrying case that slips onto belts for convenience and mobility.

Standard Features of Lever Hoists to Jot Down

- Compact & lightweight

- Ideal for restricted areas with low headroom

- Usable in inverted or angled position

- Durable in nature

- Galvanised

- Hardened alloy steel chains

- Lifting capacity is near 750kg

- Lifting height can be up to 1.5m

- Mechanical brake

- Free chain adjustment feature

- Features shafts, pinions and gears

When stating technically about the manual chain hoists, they are the lightest hoist type which is made from heavy-duty loop cables with gears embedded into it. This chain hoist can be found as a part of the towing system of a truck and uses a chain affixed on the manual hoist gears.

Let’s read the 2 basic types of manual chain hoists-

- Lever pullers (Ratchet hoists)

- Hand chain hoists

Lever pullers are also termed as ratchet hoists and used for lifting and pulling items in any rigging process. They are designed to move loads both vertically and horizontally. Their compact design makes them fit in tight quarters.

Hand chain hoists, on the other hand, are the most economical way to carry even the heavy loads effortlessly. This hoist design is equipped with 2 chains, namely hand chain and lifting chain. The lifting chain is allowed to move upwards or downwards in case hand chain is pulled in a single direction.

Sum Up

Manual chain hoists can serve the purpose of rigging an equipment into a place or precisely placing some of its parts into a machine. Using a manual chain hoist is an economical way to lift a load in different areas including manufacturing, construction, mining, etc.

Author Bio

Author is an expert Bishop member who loves to write informative articles related to the safe use of commonly used lifting equipment such as manual hoists, lever hoists and electric chain hoists.